There’s a common misconception that modular buildings are all about function over form – basically, people imagine little more than a tin box with the bare basics. And perhaps in the early days of mining camps, “donga” accommodation was pretty spartan. But modular doesn’t have to mean minimal. In fact, when done right, modular facilities can offer a level of comfort and quality that rivals traditional construction. For Remote Group WA, ensuring high fit out and finish standards is a point of pride. Why? Because the professionals and workers living or operating in these remote buildings deserve more than the bare minimum – and because a well-finished environment simply performs better over time. Let’s explore how we approach fit out and finishes for modular builds, proving that going modular doesn’t mean skimping on quality.

Delivering Comfort in the Bush

Life on a remote site is challenging enough. Long shifts, extreme climate – when personnel come “home” to their accommodation or step into a site office, the environment should be inviting and comfortable. That’s why the fit out of modular buildings matters so much:

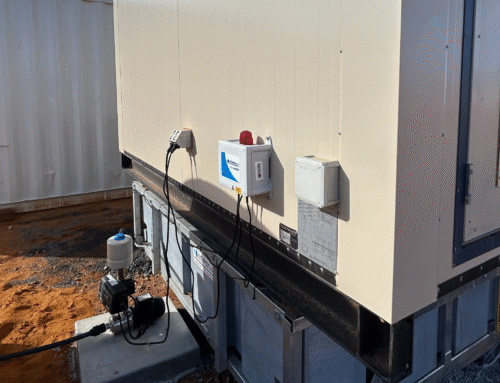

- What Fit out Includes: We’re talking about all the internal elements that turn a steel-framed module into a liveable or workable space. This covers flooring and floor coverings, internal walls and ceilings (with proper insulation and durable linings), doors and windows (with secure locks and flyscreens, given the outback insects!), lighting and electrical outlets, plumbing fixtures in wet areas, cabinetry and storage and often appliances and furniture. Essentially, everything you’d expect in a building’s interior – just within a modular shell.

- Finish Quality: Finish goes hand-in-hand with fit out. It’s the attention to detail – smooth plasterboard joins, durable paintwork, cabinetry without gaps or rough edges, properly sealed flooring and all the final touches like skirtings and architraves neatly done. In a tropical or desert climate, finishes also mean choosing materials that can handle the heat, dust and heavy use (think robust vinyl flooring that’s easy to clean, or commercial-grade laminates that won’t warp in 45°C days).

- Creature Comforts: Just because a building is relocatable doesn’t mean it should feel temporary to the user. We ensure small touches are in place: efficient air conditioning in each occupied space (essential in the Pilbara heat), adequate lighting (often LED for longevity and low power use) and small touches like blackout curtains for day-sleeping shift workers or extra power and data points for all modern conveniences. The goal is that when someone steps inside an RGWA-installed modular building, they might momentarily forget they’re in a remote location. They have a functional, pleasant interior that helps them rest or work effectively – which is ultimately in the client’s best interest too (happy staff are more productive, as any camp manager knows).

RGWA’s Fit Out Standards – Going Beyond the Basics

At RGWA, we set clear standards for our modular fit outs that go beyond the bare minimum:

- Fully Turnkey Interiors: We aim to hand over buildings that are ready to use from day one. If it’s accommodation, we include and install the furniture and appliances. Beds, mattresses, wardrobes, desks, chairs, split-system air conditioners, refrigerators, televisions – all those comforts are put in place by our team. If it’s a kitchen or dining facility, we’ll handle the stainless steel benches, the commercial cooking equipment, right down to the rangehoods. By doing so, we remove the client’s headache of kitting out the building; they open the door to a complete setup.

- Quality Materials and Workmanship: Remote doesn’t mean rough. Our tradespeople take pride in good workmanship – whether it’s the tiling in an amenities block or the finish carpentry for a laundry bench. We choose materials known for durability in regional conditions: for example, moisture-resistant cabinetry in humid coastal areas, or extra-rugged epoxy floor coatings where heavy work boots will tromp through. All electrical fixtures are industrial grade (yet still user-friendly in appearance) so they don’t fail due to a bit of dust. We also favour simplicity in design that equals reliability – fewer fiddly bits that can break under stress.

- Meeting (and Exceeding) Standards: Compliance is the baseline, but we try to go a step further when it makes sense. If the code says a door needs a certain fire rating and self-closer, we’ll of course do that. We also think about accessibility – making sure our buildings meet disability access requirements (AS 1428) where relevant, even if not explicitly asked, because it’s good practice. We build in robust safety features like ample RCDs, exit signage and emergency lighting – often beyond the minimum so there’s redundancy. In some recent builds, independent inspectors commented on how thorough the safety fit out was – a testament to our above-and-beyond approach.

- Consistent Aesthetics: While function is paramount, we don’t ignore form. Especially when delivering a group of buildings together (say, an entire camp or a facility with multiple modules), we ensure finishes present a cohesive, professional look, even matching colours to a client’s branding or adding custom touches in common areas to avoid that “barracks camp” feel. It may be as simple as coordinating paint schemes and flooring across all units, or as bespoke as incorporating a client’s logo colours or local design motifs into feature walls. The idea is that the completed facility looks intentional and welcoming, not like a hodgepodge of temporary boxes.

The bottom line: Our internal standard is that a modular building should feel like a well-built, modern building, period. Not a makeshift solution, not second-rate. We often say that if we’d be comfortable living in it for an extended period, then it’s good to go for our clients.

Case Examples: From Bedrooms to Kitchens

To put theory into perspective, here are a couple of brief examples of RGWA fitout and finish in action:

- Mining Camp Expansion (Accommodation Units): In the Sunrise Dam 100-person village expansion, we delivered 26 new accommodation modules and a laundry building. Each bedroom came fully furnished and move-in ready, right down to the small fridge and television in every room. The laundry was fitted with industrial-grade washers, dryers and a deep utility sink. We built covered verandas along each row of rooms with proper decking and handrails, providing not just visual appeal but practical outdoor shade and weather protection. Importantly, all these elements – from beds to verandas – were part of our scope, ensuring the end users had a seamless living environment from day one.

- Remote Caravan Park Upgrade (Kitchen/Dining Facility): As part of an upgrade for a caravan park that houses workers, we installed a new modular kitchen and dining hall using several joined modules. We didn’t stop at the shell – our team handled the full internal fit out: commercial kitchen appliances, stainless steel prep surfaces, commercial vinyl flooring with coved edges for hygiene and even the installation of the dining furniture. By the time we were done, the facility looked like a contemporary café you might find in Perth, except it was in the northern Goldfields. In fact, visitors reportedly couldn’t believe it was a modular building given how high-quality the interior turned out.

These examples show that the difference is in the details. Each time, the feedback we get is that the facility didn’t just meet the functional brief, it actually made life out there a bit better – and that’s thanks to the attention paid to fit out and finish.

Why It Matters: Longevity and Satisfaction

Investing in good fit out and finish isn’t just about making things look nice; it pays off in very practical ways:

- Durability: High-quality finishes last longer. In remote projects, maintenance is harder (you can’t get a repairman out in an hour), so everything we install is chosen to reduce the need for fixes. Proper waterproofing in bathroom modules, for instance, means fewer leaks and rot issues down the track. Using the right paint or coatings means you won’t be repainting due to sun damage every year. The longevity of our work at sites we completed a few years ago stands as proof – those buildings are still in great shape, saving clients money over time.

- User Satisfaction and Morale: There’s a human factor. Workers and staff housed in comfortable, well-finished buildings tend to be happier and less fatigued. A mining camp with decent rooms, a nice mess hall and good recreational amenities can help with staff retention – people don’t dread coming back to site as much. For clients, that’s a huge benefit. We’ve heard from camp managers that after an RGWA refurbishment or expansion with upgraded facilities, the mood in the camp noticeably improved. That’s intangible value, but very real.

- Professional Image: For facilities that host visitors or executives – say a regional training centre or a mine site during investor tours – the quality of the infrastructure reflects on the organization. Well-finished modular buildings signal that the company cares about doing things properly. It dispels the notion that they’ve cut corners. In government projects like community facilities, good finishes show respect for the end-users and the public.

- Compliance and Performance: Finally, a focus on fit out quality ensures compliance isn’t compromised. Sometimes doing the bare minimum can inadvertently lead to issues (like cheap vinyl flooring peeling up and becoming a trip hazard, or lack of proper ventilation leading to mould). By aiming higher, we inherently build in a buffer above the compliance baseline, which keeps the facility in the safe zone longer without urgent maintenance.

Modular construction gives us the speed and flexibility needed for remote projects, but it should never be an excuse for sub-par quality. RGWA’s approach is to marry the efficiency of modular building with a no-compromise attitude on fit out and finish. We operate on the principle that if you walked into one of our buildings without knowing it was modular, you’d just say “this is a solid, nice space” – not “this feels like a prefab.” By maintaining high standards, we ensure that our clients get the best of both worlds: quick, efficient builds and end products that truly serve their people and operations well. In remote WA, that combination is key to building infrastructure that lasts and makes a positive impact.