When people hear “modular buildings” or “transportable camp,” they might picture sparse, utilitarian dongas with four walls and a roof – nothing more than the bare essentials. There’s a lingering myth that modular construction equates to minimal quality or spartan living/working conditions. Remote Group WA is here to bust that myth. We firmly believe (and have proven) that modular doesn’t mean minimal. In fact, our projects show that modular facilities can be just as comfortable, well-designed and high-quality in fitout and finishes as any traditional build – sometimes even better, thanks to controlled factory construction and our keen eye for detail.

In this article, we’ll explore RGWA’s fitout and finish standards, demonstrating how we deliver not just functionality in remote builds, but also comfort, aesthetics and durability. From design sensibility to community well-being, we ensure that our modular projects are places people want to live and work in, not just have to.

High-Quality Interiors: Comfort in Every Module

Step inside an RGWA-completed modular accommodation or office and you might forget you’re in a “transportable.” We prioritize quality interior finishes to create a pleasant environment:

- Flooring and Surfaces: We use commercial-grade flooring (often vinyl or hybrid plank in living areas for durability and ease of cleaning and non-slip tiles or vinyl in wet areas). These aren’t rough plywood or bare vinyl offcuts – they are properly finished floors that can handle heavy use but still look modern. For instance, in our recent accommodation projects, we’ve installed attractive wood-look flooring that gives a more homely feel. Surfaces like benchtops and vanities are selected for longevity (laminate or stainless steel) but also style, with colour schemes that match the client’s branding or desired look.

- Joinery and Fixtures: Just because a building is modular doesn’t mean the cabinets should be flimsy. RGWA uses quality joinery for kitchens, wardrobes and storage – often manufactured in Perth or regionally to our specs and transported to site. We include ample storage in rooms where possible and sturdily built furniture (either as built-in joinery or supplied). Our approach is akin to a good hotel fitout: think durable hinges, smooth drawer runners and solid-core doors for privacy. In the Laverton Caravan Park units we installed, each 4-bedroom unit included its own ensuite bathroom per room – complete with proper shower cubicles, flushing toilets, tiled floors and modern fixtures. Those touches mean each resident has a sense of personal space and comfort, not just a tiny room.

- Climate Control: WA’s outback can be extreme – hot days, cold nights. We ensure every occupied space has appropriate insulation and air conditioning. Insulation in walls and ceilings of our modular units meets (or exceeds) the energy code, which not only helps with comfort but reduces energy usage for cooling. We also choose efficient split-system air conditioning for individual control. A quiet, well-functioning AC and a well-insulated room mean a good night’s sleep for FIFO workers – critical for their safety and well-being on the job. These are not afterthoughts but part of our standard.

- Lighting and Ambiance: Lighting plays a big role in how “liveable” a space feels. Our electrical fitout includes LED lighting with good diffusion – bright enough for tasks, but not the harsh floodlights of old mining camps. We often incorporate a mix of overhead lights and softer wall lights or bedside lamps in accommodation, giving occupants control. Where possible, we align windows and add window furnishings (blinds or curtains) for natural light and privacy. The idea is to avoid that claustrophobic, dim trailer feel; instead, create a light, airy atmosphere inside modules.

RGWA’s commitment to interior quality is part of our integrated trades promise – we have skilled carpenters, painters, plumbers and electricians on our team, which means we directly control the quality of every installation. We don’t cut corners by using substandard fixtures; our electricians, for example, will install well-rated switches and plenty of outlets (who likes a room with one power point these days?).

One anecdote: After completing an accommodation block for a resources company, we were told by the client that some of their senior staff preferred staying in the new modular units rather than the older permanent buildings on site, because the finish and comfort were superior. That’s music to our ears – modular done right can exceed expectations.

Thoughtful Design Sensibility in Modular Form

Design sensibility isn’t just for city architects – it’s equally important in remote construction. RGWA collaborates with architects and designers who understand the nuance of modular design to ensure our projects are both functional and visually appealing:

- Layout and Flow: We pay attention to how spaces will be used. In a modular office, for example, we consider noise separation (maybe putting meeting rooms or kitchens between offices to buffer sound), natural light (strategically placing windows or even skylights) and flexibility (open-plan areas that can be reconfigured). In accommodations, we think about privacy (spacing units or using insulation and staggered layouts to reduce noise between rooms) and community (does the design allow for a small patio or common area where people can relax together?). Our Boomers Village expansion included a new gym and laundry in Stage 1 – facilities that significantly improve daily life for residents. We designed those spaces to be inviting: the gym with proper ventilation and durable flooring for equipment, the laundry with sufficient room and drainage for multiple machines to operate comfortably.

- Aesthetics and Community Fit: A big part of design sensibility is making sure a building doesn’t feel like an alien shoebox dropped from the sky. That means choosing exterior colours and finishes that blend with the environment or the company’s identity. We often use Colorbond cladding in earthy tones (think muted greens, browns, or stone colours) that match the Pilbara red earth or Goldfields scrub, rather than an industrial grey or bright white that would glare under the sun. We also incorporate design elements like verandas, breezeways and covered walkways to add depth and visual interest to the structures. These aren’t just aesthetic; they create shaded outdoor spaces, encourage interaction and respect that outdoor living is part of Aussie life, even on worksites.

- Community and Cultural Awareness: When working near or within communities, we strive to reflect local needs and values. For example, if we were designing a community centre in a regional town using modular construction, we might integrate a facade style that resonates with local architecture (like a gable roof or a wraparound porch common in farm areas). On indigenous community projects, we would consult to possibly include elements of cultural significance (colours, artwork) into the design. Even in workforce camps, acknowledging the “community” of workers matters – like creating a central courtyard or common room to foster camaraderie. RGWA aims to build places that people feel connected to, not just bided time in.

One of RGWA’s advantages is our Design–Document–Certify capability (as listed on our service menu), meaning we can take a concept from initial design right through to engineering and certification. This means we incorporate design thinking at every stage, rather than just erecting cookie-cutter boxes. Modular is just a construction method; the design still needs a human touch.

Premium Fit and Finish – Built to Last

Durability is a key aspect of finish quality. Remote facilities see heavy use – miners coming off shift, tracking in red dirt; machinery workshops where floors and walls take a beating. Our finish standards emphasize robustness:

- Materials Selection: We choose materials that can handle the remote environment. For example, we often specify marine-grade paints and finishes on external metalwork to resist corrosion from outback conditions. Indoor paints are typically washable low-VOC types to allow easy cleaning of scuffs (important for high-traffic corridors or mess halls). If we use tile, we pick through-body porcelain tiles that won’t crack easily. Even something as small as door hardware – we opt for heavy-duty door closers and kickplates knowing that doors might get a lot of use and occasional abuse.

- Workmanship: Quality materials demand quality workmanship. RGWA’s crews take pride in their craft – as evidence, consider that at Castle Hill every element was “planned and poured to spec” and closely quality-checked. That level of care extends to fitout. Our tilers ensure a proper fall in the shower floors (no puddles left behind). Our cabinet installers shim and level every kitchen unit so you don’t get wobbly shelves. And before we hand over, we do a thorough walkthrough as if we were the client moving in: testing drawers, latches, checking silicone seals in bathrooms, making sure paint edges are neat. We address any snags because we have all the trades on hand to do so, rather than leaving minor defects as “good enough for the bush.” Good enough is never good enough – we aim for city-quality finish in remote builds.

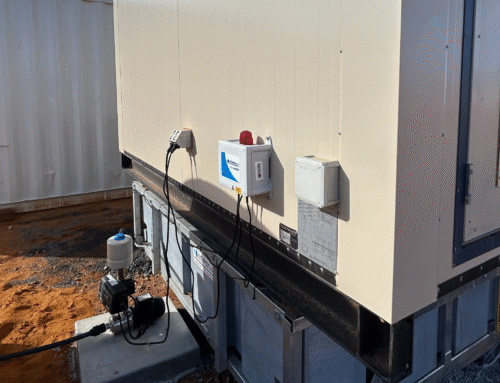

- Innovations and Upgrades: Modular doesn’t have to lag in tech or features. We can integrate solar panels on roofs for energy efficiency if the client desires, or modern amenities like wireless access points in each module for strong internet (critical for morale when people want to Skype home from camp). We keep up with industry improvements – for example, new insulated panel systems that improve thermal performance, or composite materials that are lighter and stronger. Incorporating these means the final product is cutting-edge, not an outdated donga. Our integrated model allows us to propose these upgrades and implement them without needing a slew of subcontractor agreements.

To illustrate, one of our fitout successes was the refurbishment of some old mining camp buildings we undertook. We took decades-old, tired modules and “restored [them] to modern standards” – installing new linings, floors, fixtures and ensuring they met current codes. When finished, you’d be hard-pressed to tell they weren’t brand new. That’s the power of quality fitout: it can completely rejuvenate a structure. It also speaks to sustainability – reusing and refurbishing is far greener than scrapping and rebuilding and RGWA has the capability to do it without sacrificing quality.

Case in Point: Beyond “Minimal” in Recent Projects

Let’s revisit a couple of RGWA projects to see how “modular doesn’t mean minimal” in action:

- Boomers Village Expansion: This was a two-stage project adding living quarters and amenities to a mining camp. Instead of just rows of bedrooms, we delivered a holistic living environment. Stage 1 included a gym and laundry – acknowledging that wellness and convenience matter for workers. We built verandas so people had shaded outdoor space to relax. We also ensured full service connections, meaning those new buildings had reliable hot water, power and sewage from day one. The presence of recreational and service facilities elevated the camp from mere sleeping quarters to a mini-community.

- Laverton Caravan Park Upgrade: Here, we installed multiple 4-bedroom, 4-ensuite units and expanded a dining facility with modular buildings. The “minimal” approach would have been to drop the units in and call it a day. RGWA did much more – we landscaped with breezeways connecting units to the dining hall, creating a cohesive complex. By including breezeways (essentially covered, ventilated corridors/outdoor patios), we provided shelter from sun and rain and a social walkway where people can greet each other – a small town feel. And by outfitting the kitchen/dining with appliances and proper finishes, we turned it into a true communal hub, not a basic mess. The result: a facility that felt established and comfortable immediately, despite being built fast with modular components.

- Sunrise Dam Village Expansion: Adding 100-person capacity to a remote mine camp could have been done with a cookie-cutter approach. However, RGWA integrated the new units with the existing village seamlessly. We ensured the finish and specifications of the new rooms met modern standards, likely even better than some older parts of the camp. We also installed a new laundry building – and that wasn’t just a shed with machines; it was a fully plumbed, ventilated facility for industrial washers, with proper drainage and tiling to handle muddy work clothes. We delivered it all with zero compromise on quality and importantly, with minimal impact to ongoing operations, meaning we coordinated works so that existing residents weren’t disturbed – a respectful approach to community wellbeing on site.

Fit-for-Purpose, Not “One Size Fits All”

The “minimal” mindset often comes from one-size-fits-all solutions – the idea that a transportable box is the same everywhere. RGWA rejects that. We take a fit-for-purpose approach:

- If a client needs a high-end executive accommodation in a remote area, we can outfit modules with premium finishes (think bigger rooms, better furnishings, even luxuries like an outdoor deck or ensuite per room).

- If the purpose is a classroom in a remote community, we focus on natural light, good acoustics and durable child-friendly finishes (washable paints, pin-up boards, etc.).

- For a field laboratory, we’ll include specialized benches, fume control and robust flooring that resists spills.

- For workforce camps, we choose finishes that balance comfort with easy maintenance – e.g. vinyl floors that are comfy enough but can be cleaned daily, or semi-commercial fixtures that can handle higher usage.

“Fit-for-purpose” also means we consider how the facility will be operated. We might choose slightly more expensive plumbing fixtures that are more reliable, to reduce maintenance calls (imagine a leaking faucet 500 km away – better to avoid that altogether). Or in community housing projects, using materials that residents can repaint or repair easily with local resources.

At the core of this is listening to the client and end-users. RGWA often works closely with facility managers or end-user reps to get these details right. It’s the kind of attentiveness you expect from a boutique builder and we bring it to modular construction.

The Bottom Line: Raising the Bar for Modular in WA

We’ve entered a new era where modular construction isn’t a compromise on quality – it’s an alternative that can deliver equal, if not superior, results in less time. Remote Group WA’s projects stand as proof: you walk into our completed buildings and you experience solid construction, thoughtful design and comfort – not a “site shed” vibe. We insist that remote workers, community members and operators deserve the same level of amenity and finish as anyone else.

By leveraging our integrated trades, attention to design and commitment to high standards, RGWA ensures that modular builds are something to be proud of. The next time someone says “It’s just a transportable,” we invite them to step into one of our completed facilities – say, the new dining hall and units at Laverton – and see the modern kitchen with stainless appliances humming, people enjoying a meal in a well-lit, air-conditioned room and others relaxing under the breezeway at dusk. That’s when it clicks: modular can be more than tin cans and basic shelter. With RGWA’s approach, modular means efficient delivery, yes, but with maximal quality and care.

In conclusion, modular doesn’t mean minimal – not in looks, not in comfort and not in longevity. It’s all about who delivers it. With Remote Group WA, you get a partner who treats a modular project with the same pride and craftsmanship as a bespoke build. And that means a finished product where people can thrive, communities can grow and clients can truly say they got a premium result in a remote package.

Modular Camps & Workforce Accommodation Supply and Installation Regional WA