Modular construction is often sold on the idea of speed and simplicity: build in a factory, drop it on site and you’re done. The impression is that a modular building might just need a flat piece of ground and hookups and—voilà. In reality – especially in remote Western Australia – some degree of civil works is almost always required. Skipping proper civil preparation is a bit like skipping foundations for a traditional build: it might stand for a while, but you’re asking for trouble down the track. So, when does a modular project need civil works and why are they so important? Let’s break it down with a practical lens from our experience in the field.

What Counts as “Civil Works” for a Modular Project?

First, let’s clarify the term. Civil works in the context of modular builds includes any site preparation and infrastructure construction needed to support those modules. Common elements are:

- Earthworks and Site Prep: Clearing vegetation, levelling the ground and compacting soil or gravel to create a stable pad. In remote WA, this might mean bringing in fill to build up a pad above flood-prone ground or cutting into a slope on a hillside camp.

- Foundations and Footings: Even if modules have their own floor structures, they usually need something solid to sit on. This ranges from concrete slabs or strip footings, to piers, steel posts, or screw piles. For example, an array of accommodation units might be placed on dozens of small concrete footings, while a large modular office could need a full slab if heavy equipment will be inside.

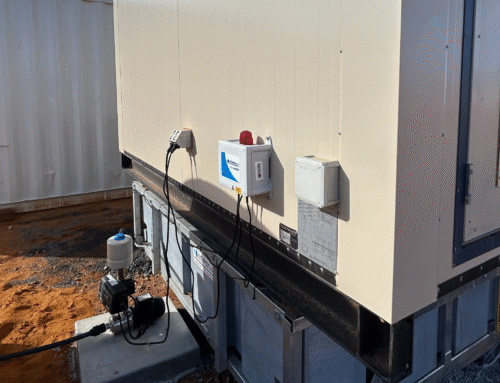

- In-ground Services: Trenching and laying pipes for water, sewer and stormwater, plus conduits for power and communications. Without this groundwork, your modular building would be a disconnected shell. If the site is off-grid, civil works could also include installing septic systems or water tanks and rigging up connections to generators or solar arrays.

- Access and Drainage: Forming access tracks or roads to the site, parking areas and shaping the land for proper rainwater runoff. In the flat, arid landscapes of regional WA, a sudden rain can cause flash flooding, so sculpting the ground for drainage (swales, culverts, drains) is key to prevent water pooling around your buildings.

In short, civil works cover everything that turns an empty patch of earth into a ready-to-build-on site with the necessary infrastructure. It’s the canvas on which your modular building will sit. Without it, you may have a building, but it won’t be functional or long-lasting.

When Are Civil Works Necessary? (Almost Always)

There’s a simple answer: nearly every permanent or semi-permanent modular installation in a remote setting will require some civil works. The extent can vary:

- Short-Term vs Long-Term: If you’re placing a small, temporary site office for a 3-month exploration project, you might get away with minimal prep – perhaps compacted ground and some timber skids, especially if it’s dry season. But anything longer-term (a year or more) or larger in scale will need proper foundations and services. In our experience, even “temporary” camps often end up staying longer than planned, so it pays to do it right from the start.

- Size and Complexity of the Build: A single, standalone modular classroom might have modest needs compared to a 100-person accommodation village with ablution blocks, kitchens and laundries. The latter will definitely entail extensive earthworks, concrete paths, underground plumbing, electrical reticulation – the works. For instance, in one 100-room mine camp expansion we undertook, the project included not just placing the modules but also road works and almost half a kilometre of concrete footpaths to tie the new buildings into the site.

- Ground Conditions: The local terrain dictates a lot. Soft or sandy soil (common in coastal Pilbara areas) might require deeper foundations or soil stabilisation. Hard rock (like in parts of the Goldfields) could mean using specialized rock anchors or blasting to create level pads. And if the site has any slope, you’ll be looking at cut-and-fill earthworks or stumped footing systems to create a level base.

- Climate and Region: In cyclone-prone regions of WA (Region D in the building code), civil works have to account for high wind loads and heavy rain. That means more robust footings, cyclone-rated tie-downs into the concrete and careful attention to drainage so buildings aren’t sitting in water during monsoonal rains. In a bushfire-prone zone, clearing vegetation and creating fire breaks around structures might be mandatory – which, again, is part of civil works on the project.

In essence, civil works are necessary whenever you want your modular setup to be safe, compliant and suited to the site’s conditions. If someone claims “no civil works needed” for a substantial remote installation, it’s wise to be sceptical – or at least double-check what that implies. The laws of physics and the elements still apply to modular buildings.

Why Skimping on Civil Works is a Bad Idea

Let’s say you’re tempted to cut costs or save time by minimising site works. What could go wrong?

- Foundation Failure: The worst-case scenario – a building that shifts, cracks or even tips because it wasn’t properly supported. We’ve seen instances where inadequate footings led to uneven floors, doors that wouldn’t close and plumbing that leaked due to movement. Considering the investment in the modular units themselves, it’s a huge risk to place them on poor foundations.

- Water Damage and Erosion: Ignore drainage and you might find your nice new portable offices sitting in a muddy pond after the first big rain. Erosion can wash away soil from under footings or create channels that undermine paths and supports. Many remote sites in WA have hard clay that suddenly turns to soup with water – without proper earthworks and drainage, a quick downpour can wreak havoc.

- Service Failures: Skipping proper trenches or conduit for utilities can lead to power cables or pipes getting damaged. We encountered a case where makeshift surface-laid plumbing (instead of buried pipe) for a “short-term” camp became a hazard – vehicles drove over lines and extreme temperatures degraded the materials quickly. Proper civil works (trenching, bedding, backfill) would have avoided these issues, even for a temporary setup.

- Non-Compliance: There’s also the legal side – building codes and site regulations often require these works. If an inspector comes by (which can happen even on remote mines or government projects) and finds footings or site prep doesn’t meet the required standard, you could face costly retrofits or even a stop-work order. It’s simply not worth the shortcut.

In summary, trying to save on civil works is a classic false economy. The price of fixing foundation problems or reworking site infrastructure later far exceeds doing it properly upfront. And in remote areas, those fixes are even more expensive and logistically difficult to carry out.

The RGWA Approach: Integrating Civil and Build from Day One

So how do you effectively incorporate civil works into a modular project plan? The key is integration. At RGWA, we’ve found success in treating the civil phase and the building installation as one integrated process rather than two separate jobs. Here’s how that helps:

- Unified Design and Planning: We involve our civil engineers and building installers together in the early design phase. This ensures the foundation plans perfectly match the modular building specs. For example, if a building supplier provides column locations for stumping, our team will design footings to align exactly. No guesswork on site, no retrofitting later.

- Concurrent Work Streams: Remote schedules are tight, especially when mobilization costs are high. We often start site works while the modular units are still in manufacture or transit. By the time the modules arrive, the earthworks are done, trenches dug and concrete cured. This parallel approach shaved weeks off the schedule in a recent project where a new camp’s accommodation buildings were being built off-site while we poured slabs and laid services on-site simultaneously.

- Single Point of Responsibility: Because RGWA self-performs both civil works and building installation, there’s no finger-pointing between contractors. If an unexpected issue with the site arises – say we hit an old buried pipe or encounter harder rock than anticipated – we adjust in-house and keep moving. Contrast that with a scenario where one company does the dirt work and another places the buildings: any mismatch can lead to “that’s not our problem” delays.

- Quality Control and Compliance: Our project managers oversee the whole package, which means they ensure the civil works meet all requirements before the buildings go on. We’ll check compaction test results, rebar inspections, plumbing pressure tests, etc. as part of our workflow. The result is that once the modular units are installed and connected, we don’t get nasty surprises during final inspections – everything from the soil underneath to the roof on top has been done to standard.

This integrated method is essentially an end-to-end approach for remote construction and it’s particularly valuable in WA’s far-flung locations where rework is costly. It means our clients get a turnkey outcome: the building ready to occupy and perform, underpinned by invisible but vital civil work done right.

Civil works are the backbone of a successful modular build in remote regions. They may not be as visible or exciting as a building being craned into place, but they are absolutely crucial for safety, longevity and compliance. Understanding when and why to do civil works comes down to acknowledging that even a “modular” project follows the same principles as any construction: it needs a solid foundation, good infrastructure and adaptation to its environment. Do it right and your modular development will stand proud against the challenges of time and the elements, which is exactly what we aim for every time we break ground on a new project.

Modular Camp Civil Preparation