Relocating modular buildings across the vast distances of Western Australia is no small feat. Picture a convoy of oversized trucks hauling accommodation units down a dusty highway, racing to beat the wet season rains. Whether it’s moving a mining camp to follow a new ore body or transferring portable offices to a fresh project site, the process requires meticulous planning and local know-how. In remote WA, factors like extreme climate, limited infrastructure and stringent regulations all come into play. Here, we explore the key considerations to ensure a smooth and successful modular building relocation, drawn from hard-earned experience in the field.

Plan Ahead and Assess Both Sites

Every successful relocation starts long before any truck is loaded. Early planning is essential:

- Source and Destination Assessment: Evaluate the current site (for safe removal of structures) and the new location (for suitability and required preparations). This includes checking road access, ground conditions and space for cranes and trucks.

- Stakeholder Coordination: Engage all stakeholders early – clients, transport contractors, site managers and any local authorities. Aligning schedules is crucial; for example, mining operations may have specific shutdown windows or permit requirements for heavy haulage on private roads.

- Season and Weather Timing: In WA’s regions, timing can’t be ignored. In the north-west Pilbara or Kimberley, you’ll avoid relocating during the peak cyclone season or heavy summer rains. Choosing the right season can prevent weather-related delays and damage.

Thorough planning also means anticipating challenges. We’ve learned to ask questions like: are the modules built to handle another move (structurally sound for lifting and transport)? Do we have all the necessary approvals for both removing and re-installing the buildings? Answering these early prevents nasty surprises down the track.

Regulatory and Permit Requirements

Relocating large modular buildings involves navigating a web of regulations:

- Transport Permits: Oversized loads need permits and sometimes escort vehicles on WA roads. These permits dictate travel times (often only daylight hours) and routes (avoiding certain bridges or urban areas). It can take weeks to secure approvals, especially if the convoy will pass through multiple shires.

- Local Government & Site Approvals: If the new site falls under a local shire’s jurisdiction, you may need building permits or development approvals even though the structure is pre-built. For moves within mining leases or private land, the mine operator’s consent and safety clearances are required.

- Compliance Standards: Ensure the building meets codes for the new location. For example, a unit originally installed in Perth (non-cyclonic Region B) might need upgrades to structural bracing and tie-downs if it’s headed to a cyclonic Region D area up north. Similarly, check for bushfire attack level (BAL) requirements in the new environment if it’s bushland – an area RGWA always verifies for remote WA projects after encountering strict BAL19 compliance needs on previous jobs.

Staying on top of paperwork isn’t exciting, but it’s vital. One missed permit can halt a convoy or, worse, require a costly retrofit of a building that doesn’t meet the new site’s standards. Our team’s approach is to double-check every compliance detail as part of the project plan so that nothing is left to chance.

Safe Decommissioning and Packing

Taking modular buildings apart safely is as important as putting them back together. Decommissioning involves:

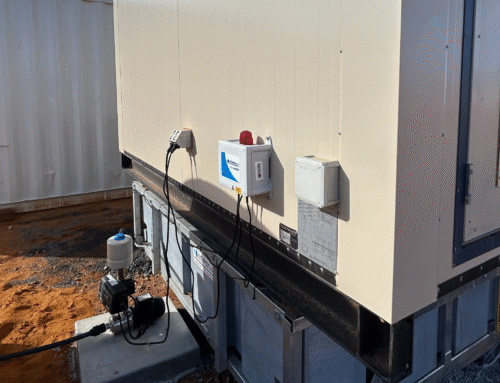

- Utility Disconnections: All services – power, water, communications, gas – must be properly isolated and disconnected by licensed professionals. (In one case, we discovered an old fibre optic line connected to a camp building that required specialist handling to avoid knocking out the site’s comms network.)

- Disassembly and Securing: Depending on design, modules might be bolted together in sections or attached to on-site constructs like verandas. We methodically reverse the installation process: remove skirtings or additions, unbolt modules and label all components (like stairs, awnings, footings) to keep them organized. Any small parts (nuts, bolts, brackets) are bagged and tagged so they don’t vanish in the red dirt.

- Assessing Module Condition: Before lifting a module, our crew inspects it for structural integrity – checking frames, weld points and any wear from years of service. It’s crucial to reinforce or repair weak spots now (for instance, adding temporary bracing inside a unit) so that the building isn’t damaged during the journey.

We treat each building like a giant jigsaw piece that needs to survive high winds on the highway. That means shrink-wrapping or tarping exposed interiors to keep out dust and rain and securing doors or loose fittings. By “packaging” modules securely, the precious cargo remains roadworthy over hundreds of kilometres of bumps and corrugations.

Logistics of Remote Transport

The transport phase often proves the most visibly dramatic – and for good reason. In remote WA, a relocation convoy can resemble a mini expedition:

- Heavy Haulage Expertise: We partner with heavy haulage drivers experienced in outback routes. These specialists know the quirks of long-distance oversized loads – from navigating narrow pastoral tracks to dealing with blinding sun at dawn and dusk.

- Convoy Coordination: Constant radio communication ensures everyone responds safely to oncoming traffic or obstacles on one-lane stretches. A well-drilled convoy can pull over and park a 30-meter road train carrying a building module as smoothly as a normal driver parks a car – but that level of coordination takes planning and practice.

- Remote Road Conditions: The quality of roads in the bush ranges from sealed highways to improvised dirt tracks. We schedule extra time in case of unforeseen obstacles – think stray cattle, flooded creek crossings, or a flat tire on a low-loader in the middle of nowhere. Carrying spares and pre-positioning a support Ute with tools can save a day’s delay.

- Fuel and Stops: Unlike city moves, outback journeys require plotting fuel stops for both trucks and escorts. On one relocation, our team organized a fuel trailer to accompany the convoy through a particularly isolated stretch where roadhouses were over 300 km apart, ensuring none of the trucks ran dry.

Through it all, safety is paramount. We adhere strictly to regulated driving hours and mandatory rest breaks; fatigued drivers and remote roads are a dangerous mix. And we always have an emergency plan – knowing the nearest roadhouse with a mechanic, or having satellite phones ready when there’s no signal. These measures mean that even if the journey is long, our modular cargo and crew arrive intact.

Reinstallation and Site Integration

When the modules finally reach their new home, the project enters a critical phase: reinstallation. This is where all the preparation pays off:

- Foundations and Set-Out: Ideally, by the time the convoy arrives, the civil works at the new site are ready. Proper foundations – whether reusing the original footings or newly poured concrete pads/piers – should be in place and verified to match the module dimensions. We double-check the set-out with survey gear to ensure each building will sit perfectly where intended.

- Cranage and Placement: Lifting modules off the truck and onto foundations requires precision. A crane suited to the weight and reach is positioned on stable ground (not always easy in soft outback soil). Our rigging crew communicates via radio and hand signals in a practiced choreography: one wrong move and a module could sway or set down incorrectly. We use experienced riggers who know modular buildings’ balance points intimately – often the same folks who decommissioned it will guide it into place, since they know the building best.

- Reconnecting Services: Once the structure is secured and tied down, we reconnect power, water, sewer and communications. This might mean running new wiring looms and plumbing lines and certainly testing everything. Licensed electricians and plumbers on our crew ensure that as soon as possible, lights turn on, water runs and air-cons hum to life. If the relocation included something like a kitchen or laundry, equipment is recommissioned and certified by specialists (for instance, a gasfitter will re-certify any gas appliances due to new regulatory requirements at the destination).

- Finishing Touches: Relocation isn’t truly finished until the buildings are habitable and functional. We reassemble any removed steps, ramps, or verandas, touch up paint or cladding that got scuffed and make sure waste systems and fire safety equipment (alarms, extinguishers) are in place. Essentially, the goal is to deliver a facility that’s as good as (or better than) it was before moving.

After everything is installed, a thorough inspection with the client confirms that nothing was lost in translation – or transit. It’s a satisfying moment to see a building come back to life on a new site, especially knowing the miles and effort invested.

Local Know-How Makes the Difference

Experience has taught us that local know-how is often the difference between a smooth relocation and a troubled one. Remote Western Australia throws curveballs – sudden road closures, unexpected weather events, even the occasional cattle drive that halts a convoy. A team seasoned in WA conditions can anticipate these quirks. For example, having worked across the Pilbara and Goldfields, we know how different soil or weather patterns affect scheduling and equipment choices. We also understand the regional protocols – from knowing whom to call for a last-minute crane in a mining town, to ensuring cultural heritage requirements are met on Indigenous lands. By leveraging this hard-earned local experience, we plan relocations with realistic contingencies and respectful community engagement, avoiding pitfalls that outsiders might miss.

In summary, relocating modular buildings in remote WA is entirely feasible with the right approach. It’s a complex dance of logistics, engineering and bush savvy. The key considerations come down to detailed planning, strict compliance, careful handling of the modules and leaning on experience to expect the unexpected. With those boxes ticked, you can turn what seems like a daunting task into a well-orchestrated move – delivering buildings from Point A to Point B and having them up and running again with minimal downtime. As we like to say after a long relocation job: the only sign that a building ever moved should be the fresh tyre tracks in the dirt.