Building anything in remote Western Australia means navigating a maze of regulations, standards and site-specific rules. Compliance isn’t the glamorous part of construction, but out in the regions it’s absolutely fundamental – for safety, legal reasons and plain old project success. Over the years, RGWA has developed an end-to-end approach that bakes compliance into every stage of a project. Think of it as a five-step roadmap. By following these steps, we ensure that a remote build not only gets done on time and on budget, but also meets all the requirements so that when we hand over the keys (or the switchboard), everything is above board and certified. Let’s walk through the five key steps to a compliant remote build.

Step 1: Thorough Planning and Approvals

Every project should start with a robust planning phase, but in remote builds, this step is particularly critical for compliance. Before any dirt is moved or module delivered, we:

- Research Regulatory Requirements: Identify what codes and standards will govern the project. This includes the National Construction Code (NCC) and Australian Standards, but also local council by-laws or specific mining company requirements if we’re on a mine site. For example, if we’re building in the cyclone-prone North West, we know upfront that Region D wind ratings will apply for structural design and if the area is bushfire prone, a certain BAL (Bushfire Attack Level) rating will be mandatory.

- Permitting and Approvals: We list all approvals needed – building permits, environmental clearances, Aboriginal heritage checks, mining lease permits, etc. – and plot out the timeline to secure each. In remote areas, even getting a shire inspector to site can take extra coordination due to distance, so we factor that in. Our project plan always includes a compliance checklist assigning responsibility for each required permit and the expected date.

- Stakeholder Consultation: Early engagement with authorities and stakeholders can smooth the path. We discuss our approach with council building surveyors, mine site representatives, or other regulators to make sure any unique conditions are understood up front. It’s easier to adjust on paper than on-site later. By getting buy-in and clarity on requirements early, we pre-empt a lot of potential issues.

By nailing down Step 1, we create a solid foundation for compliance. Essentially, no assumptions – we document exactly what’s needed to comply and get everyone on the same page from day one.

Step 2: Design and Engineering with Compliance in Mind

With the groundwork laid, the next step is ensuring the design itself will meet all those requirements:

- Code-Compliant Design: Our engineers and drafties incorporate all relevant standards into the design. This ranges from structural elements (footings and tie-downs sized for cyclone wind loads) to services (plumbing to AS/NZS 3500 standards, electrical to WA Electrical Requirements, etc.). For instance, on a remote accommodation project we integrated Region D cyclonic structural requirements and BAL19 bushfire design features into the drawings from the outset, knowing the site was in a high-wind, high-fire-risk area.

- Integrated Disciplines: Because RGWA handles multiple trades in-house, our design process is multidisciplinary. The electrical team reviews plans to ensure switchboards and generators meet safety codes. The civil team checks that earthworks plans allow for required gradients and drainage. This collaborative design step means nothing falls through the cracks – there’s no “oops, we forgot to allocate space for the fire pumps” surprises later. Each discipline brings its compliance checklist to the table.

- Third-Party Review: For critical builds, we may involve independent certifiers or client-side engineers at the design stage. Especially if it’s a high-stakes facility (like an energy installation or large camp), having extra eyes verify that the design ticks all compliance boxes can save headaches. Better to tweak drawings than to jackhammer out non-compliant concrete later.

By the end of Step 2, we have a blueprint that we’re confident can be built to code and spec. It’s essentially the map for our team to follow, ensuring that if we build as drawn, we’ll meet our compliance goals.

Step 3: Meticulous Site Preparation and Civil Works

Before structures rise, the site itself must be prepared correctly – and that’s a compliance matter too:

- Groundworks to Spec: We carry out earthworks and civil works according to the engineered designs, with an eye on quality control. Soil must be compacted to the right density (we’ll do compaction tests and keep those records). Trenches for services have to be of proper depth and bedding per regulations. For example, electrical mains often require certain separation from water pipes; we make sure those are executed on site exactly as required.

- Foundation Compliance: Whether pouring concrete footings or installing screw piles, we ensure they match the certified design. Our crews tie steel reinforcement per the rebar schedules and required cover and we don’t pour until an engineer (internal or third-party) signs off on the formwork and steel. We learned long ago that foundations are not the place to cut corners – on a remote workshop project, our strict adherence to spec meant every hold-down bolt and slab thickness was verified before concrete and the final inspection had zero issues.

- Safety and Environmental Prep: Site prep also includes setting up to meet safety and environmental requirements. That means installing any required sediment controls (so our earthworks runoff doesn’t pollute nearby soil or waterways) and delineating no-go zones if there are heritage or environmental protections. On the safety side, before major works we establish site fencing, signage, muster points and emergency comms. We treat this as part of the groundwork; a compliant site is a safe site.

Step 3 is about doing the “invisible” parts of construction right. If we vanished after this phase and an inspector came by, everything under the ground and in the setup should pass muster – that’s how we know we’re ready to proceed to vertical construction.

Step 4: Quality Execution During Construction and Installation

This is the heart of the build – assembling structures, connecting systems – and it’s where many compliance items either happen or fail. Our approach is to execute with quality and compliance as twin goals:

- Licensed Trades and Procedures: All critical works are done by qualified, licensed professionals – electricians, plumbers, gasfitters, etc. This ensures, say, the wiring isn’t just done, but done to Australian Standards and will pass any audit. Our electricians follow WA Electrical Requirements and conduct thorough testing and tagging on all installations before sign-off.

- On-Site Supervision and HSE: We keep experienced supervisors on site to monitor works and maintain safety compliance. They run daily checks – is the scaffolding tagged and secure? Are permit-to-work systems being followed for confined space or hot works? Remote sites often have additional client-specific HSE rules (mining companies, for example, are very strict). We integrate those into our daily routine so that our construction activity never violates site rules.

- Documentation as We Go: An end-to-end approach means we don’t wait until the end to gather paperwork. At RGWA, we compile records, photos, test results and certifications as construction progresses. When we cast a footing, we log the concrete batch and slump test. When we install plumbing, we record the pressure test results. This habit means by the time we reach final inspection, we have a full trail to prove everything was done right.

Focusing on quality during Step 4 has a direct pay-off: fewer defects, no scrambling to fix things under pressure and confidence that we’re building something that will not only function well but also stand up to scrutiny.

Step 5: Testing, Certification and Handover

The final step is all about validation and sign-off:

- Internal Testing & Punch Lists: Before any official inspection, we do our own rigorous testing. We energize electrical systems in a controlled manner and check every light, GPO and sensor. We run water through plumbing lines, checking for leaks or pressure drops. Any minor issues we find, we fix on the spot. Essentially, we act as our first inspector so that the official one finds a clean slate.

- Third-Party Inspections and Certifications: Depending on the project, this could involve a building surveyor for occupancy certification, an independent electrical inspector for high-voltage work, or client reps doing a final walk-through. Because we’ve followed the prior steps, these tend to go smoothly. We hand over a compliance folder with all the necessary documents – engineering certifications, test reports, as-built drawings, manuals and warranties.

- Handover Training and Briefing: Compliance isn’t just paperwork; it’s also making sure the end-users know how to operate the new facility within the rules. We often walk the client or site managers through the new installation. We explain how the wastewater treatment unit works and what maintenance is required to keep it compliant, or demonstrate how to test the RCDs in the switchboard. Especially in remote settings, giving the on-site team the knowledge to operate and maintain the infrastructure is part of leaving a fully compliant project. We want them to run the facility with confidence, knowing it was built right and how to keep it that way.

When Step 5 is done, the project isn’t just physically complete – it’s legally and operationally ready. We shake hands with the client and leave them with a building that’s fully certified and compliant with all requirements: from the local shire’s perspective, from the safety inspector’s perspective and from their own internal standards.

By following these five steps, RGWA’s end-to-end approach ensures nothing slips through the cracks. In a remote build, where logistics are tough and second chances are costly, building it right the first time is the only viable option. Compliance might seem like a paper exercise to some, but we view it as the backbone of quality and trust in construction. Each step flows logically into the next and skipping any of them can put the whole project at risk. Whether it’s a small pump station upgrade or a full camp build in the Pilbara, this roadmap keeps us on track. The result is a facility that not only stands solid in WA’s red dirt, but also stands up to every rule and regulation – giving our clients peace of mind that it was done right.

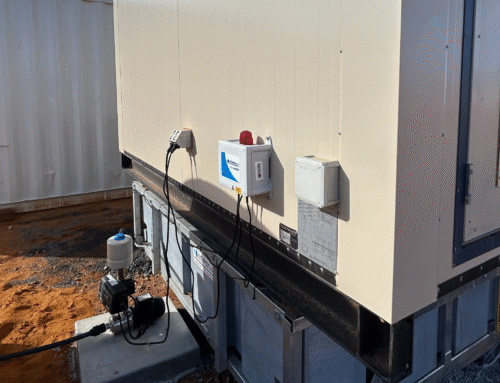

Completed Modular Camp Project at Sunrise Dam